Air Products

Client

Air Products

Location

Acheson, Alberta

Project Duration

October 2024 – Ongoing

Oil & Gas / Industrial

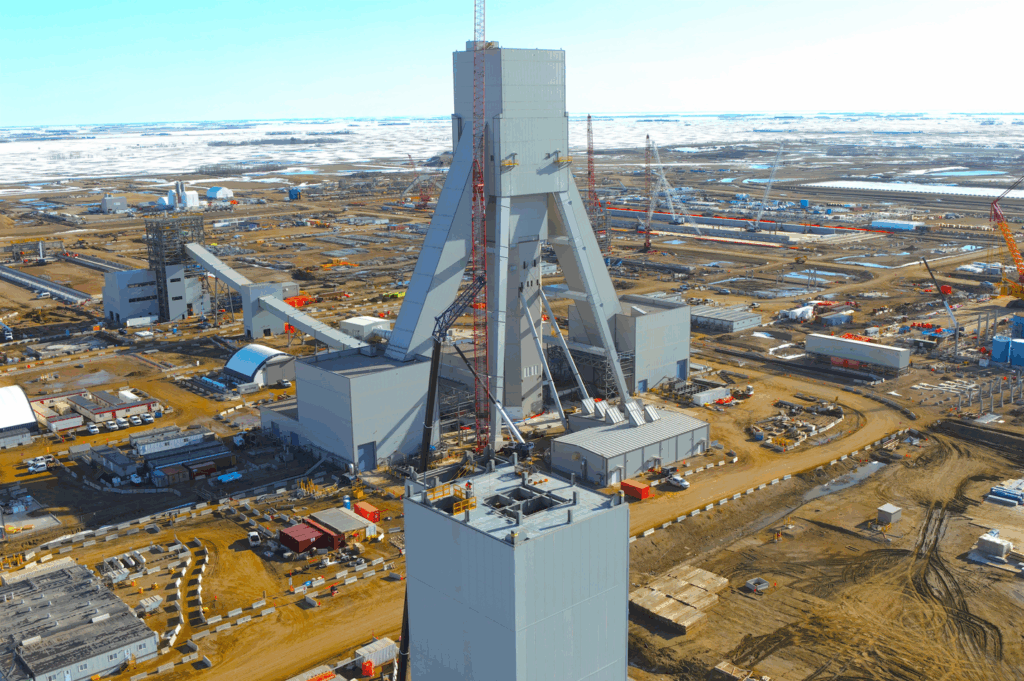

Storage for Carbon Capture and Hydrogen Production Components

Business Unit

Myshak Warehouse

Project Overview

Air Products partnered with the Myshak Warehouse to support its Landmark Net Zero Hydrogen Energy Complex, the project centered around the storage and handling of specialized equipment and components for carbon capture and hydrogen production operations. With material arriving from various suppliers around the world and destined for the high-profile industrial site in Edmonton Alberta, the scope of work included receiving, storing, and delivering a wide range of components, many of which are oversized, overweight, and required careful coordination for both safety and efficiency.

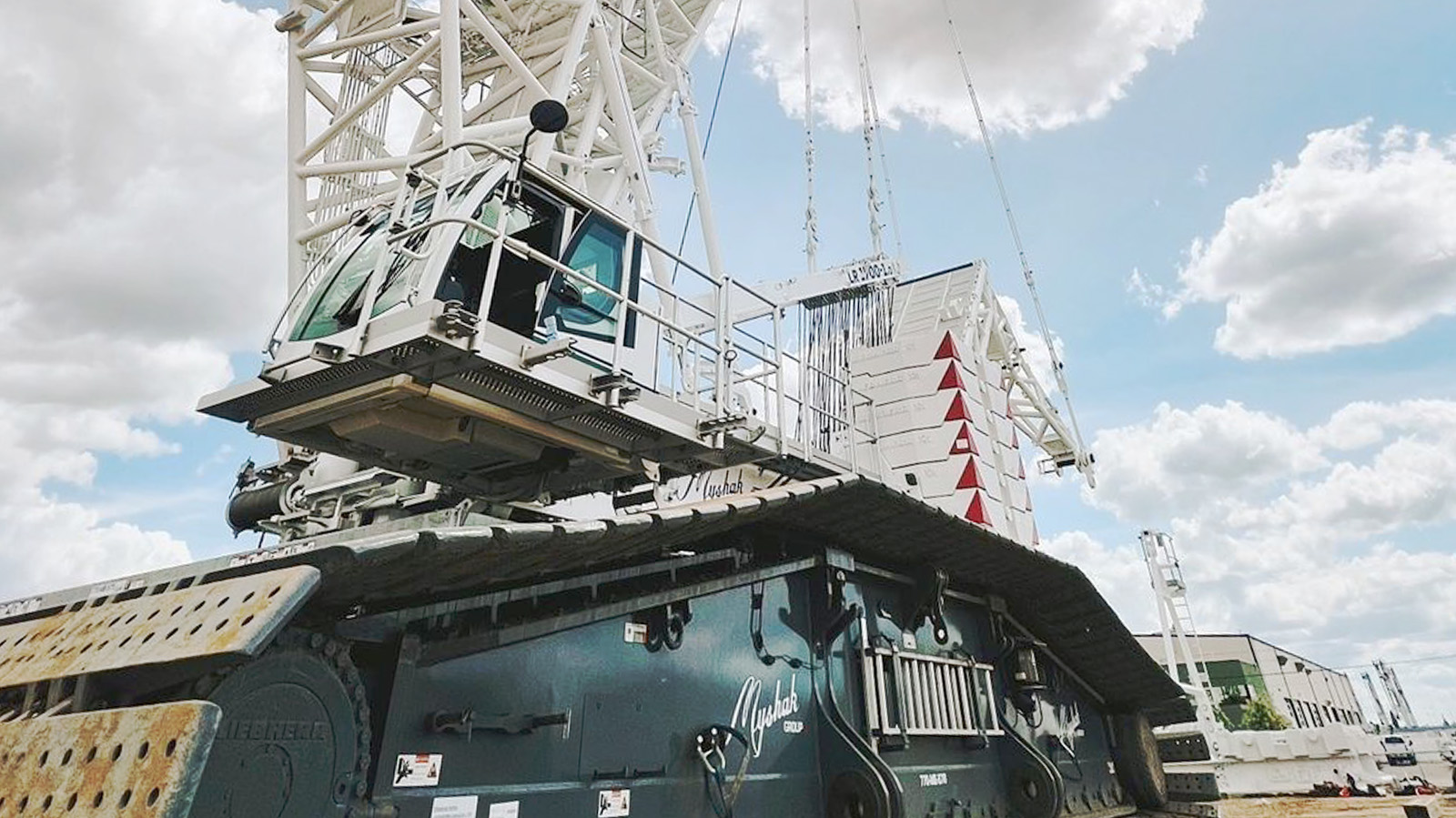

The warehouse team took on the challenge of managing 65,000 square feet of active storage space to accommodate the complex range of materials. Among the inventory were components weighing over 227,000 lbs., which demanded both technical expertise and the right equipment to safely manage their handling and storage. Key assets utilized in the the project included a 500 ton Liebherr crane, a 35,000 lbs. capacity forklift, a loader, and a newly introduced 160 ton tri glide dolly, each selected specifically to meet the demands of the project and maintain the integrity of the material.

One of the earliest challenges was the unpredictable schedule of inbound freight, which often required last minute coordination and flexible planning. The sheer size and weight of many components meant that receiving operations had to be carefully timed and aligned with both crew availability and environmental conditions. High winds and stormy weather frequently interrupted crane lifts, forcing teams to adjust their schedules while maintaining a strong commitment to safety.

To address the challenges posed by the size and weight of the components, Myshak introduced the 160 ton tri glide dolly making it possible to maneuver large loads into confined warehouse spaces without disruption to other operations.

Throughout the project, success was driven by the experience and professionalism of the Myshak Warehouse crew. Their deep knowledge of material handling and proactive coordination with the client’s logistics teams ensured that storage, staging, and delivery ran smoothly. This seamless integration allowed Myshak to function as an extension of the client’s team, anticipating needs, solving problems before they escalated, and protecting the integrity of the components throughout each phase of the project.

To date, all warehousing and material handling services have been delivered safely and without incident, despite the demanding nature of the work. By choosing to partner with Myshak Warehouse, Air Products secured a trusted storage provider capable of adapting to complex and evolving project needs, whether those involve everyday shipments or the handling of some of the largest, heaviest components in the industry.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.