Hitachi Shovels

Client

Confidential

Location

Acheson, Alberta

Mining

Outdoor Storage and Handling of Hydraulic Shovel Components

Business Unit

Myshak Warehouse

Project Overview

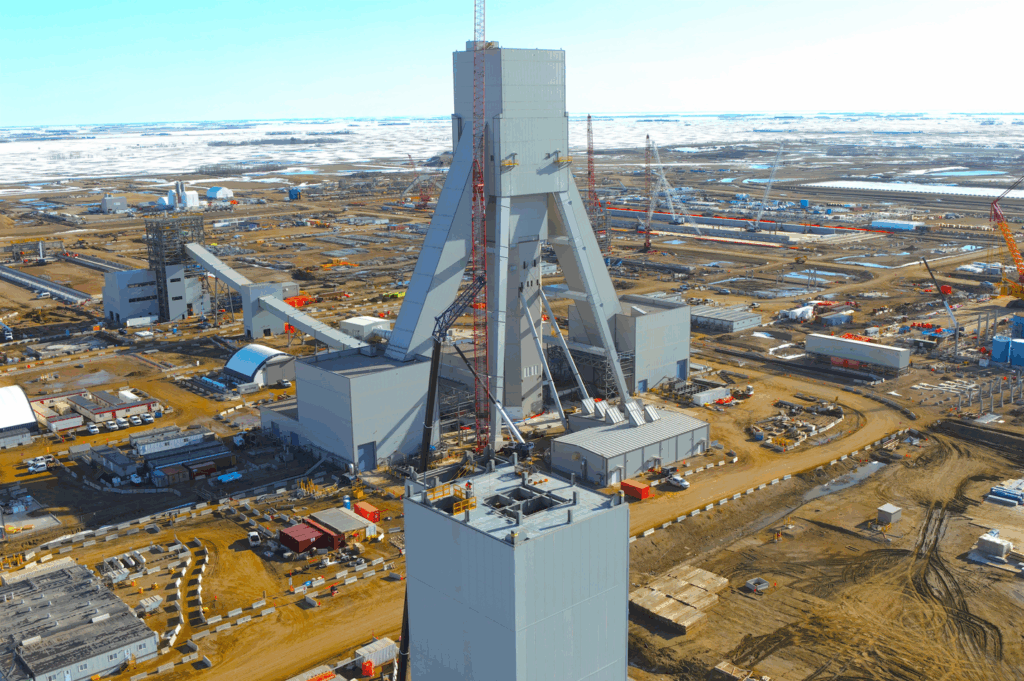

A trusted client in the mining industry partnered with Myshak Warehouse to manage the unloading, secure outdoor storage, and outbound loading of hydraulic shovel components for machines ranging in size from 2400 class to 8000 class. Given the complexity, scale, and value of the equipment involved, the project demanded a high level of precision, planning, and dependable execution to ensure each asset was protected throughout its storage duration.

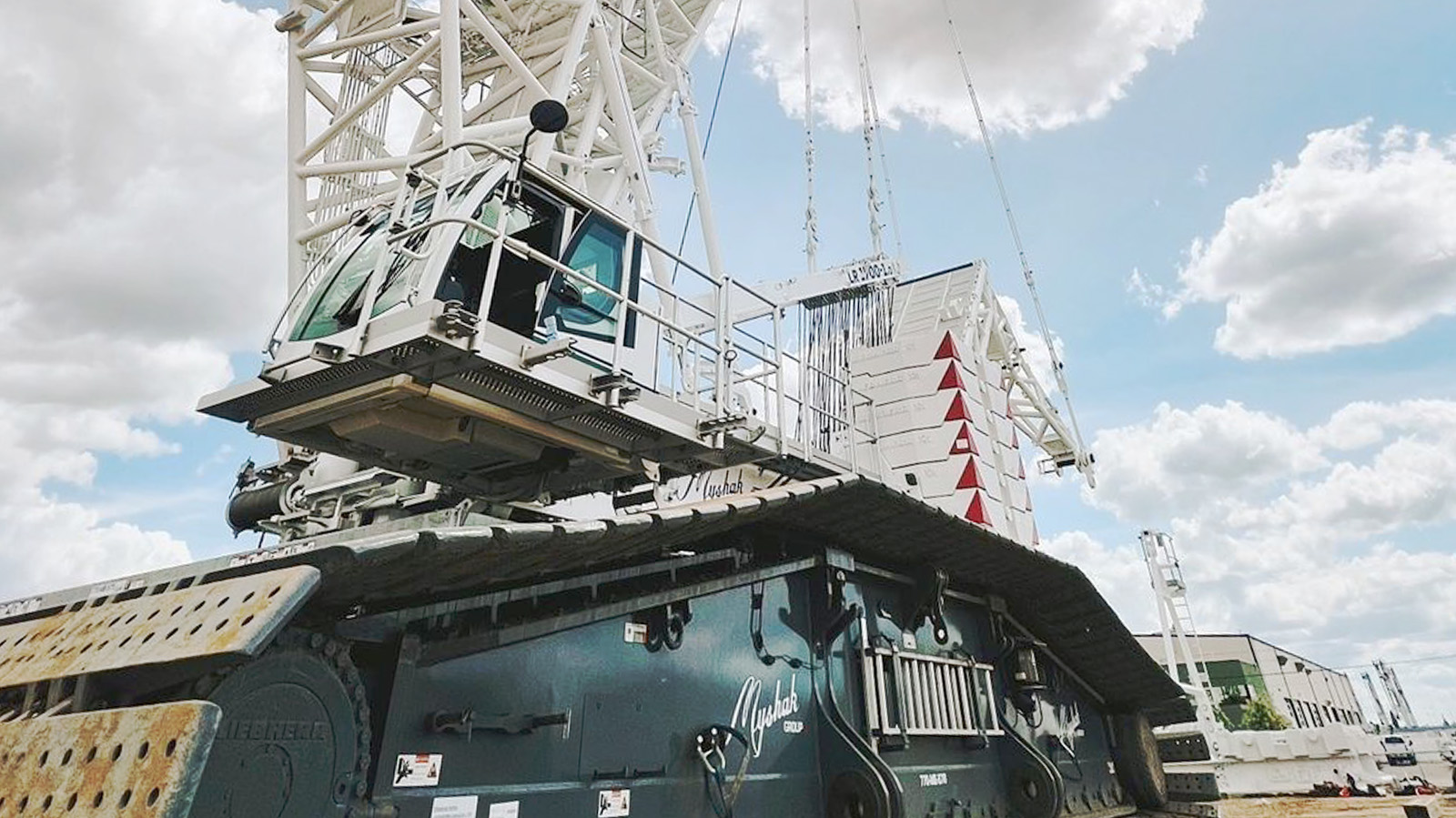

The project required receiving heavy, oversized components delivered to Myshak facilities by a third party heavy haul carrier, safely offloading each piece, positioning the components in a designated, secure outdoor storage area, and eventually reloading the equipment for shipment when required. The physical scale of the equipment made this far more than a routine warehousing task. Myshak deployed two 160 ton Tadano cranes operating in tandem to perform each lift safely and with complete control, allowing for seamless material handling even with the largest and most difficult pieces.

A technical challenge Myshak faced was the specialized rigging requirements associated with the varying shapes and the unique positioning of the lifting points on the shovel components. Standard rigging equipment would not have the ability to accommodate the range of lifting points and weight distribution required. In response, the Myshak Warehouse team relied on their internal engineers to develop an engineered custom rigging solution tailored to the specific needs of each component. These solutions allowed for precise, secure lifts that safeguarded both the equipment and the surrounding environment.

Once unloaded, components were strategically placed within a secure, clearly organized outdoor storage area designed to accommodate the footprint and structural requirements of the heavy-duty assets. Myshak’s crews, leveraging deep experience in heavy industrial handling, executed each operation with accuracy and attention to detail, ensuring the safety of personnel and integrity of the equipment at every stage.

The execution of this work reflects Myshak’s commitment to excellence. All components were safely received, stored securely, and shipped as required without incident, the client continues to rely on Myshak for ongoing support. This project demonstrates the value of partnering with a team that offers not only a strong commitment to excellence, but the right equipment, the expertise, innovative lifting solutions, and problem-solving mindset required to manage complex industrial assets with confidence and care.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.