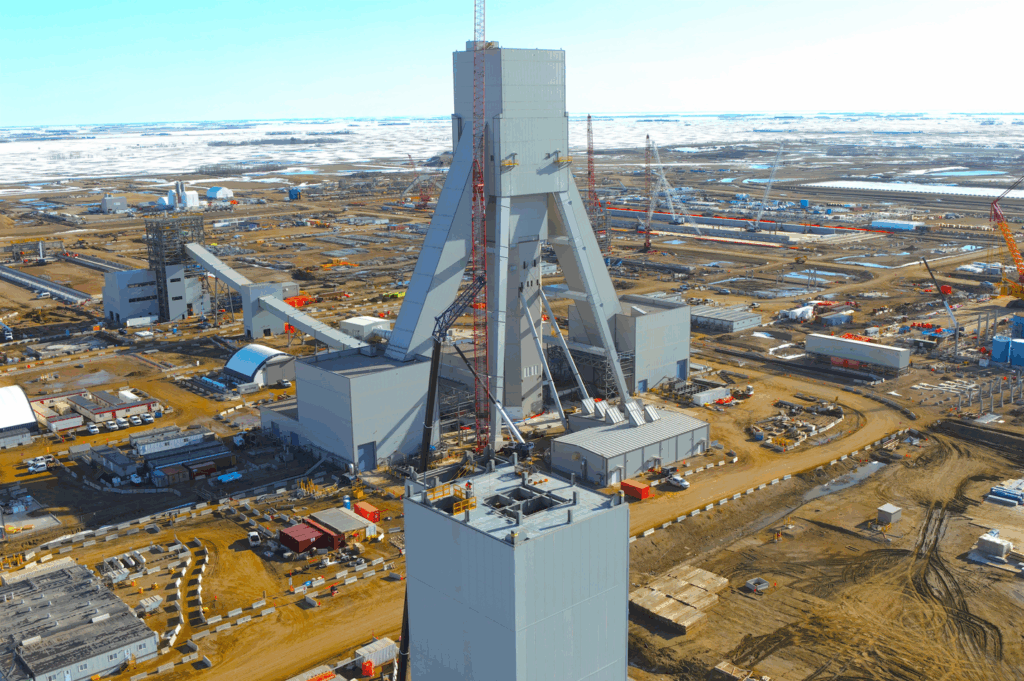

Oilsands

Client

Confidential

Location

Acheson, Alberta

Mining

Oilsands Support

Business Unit

Warehouse

Project Overview

In June of 2024, Myshak Warehouse began providing warehouse and material handling support services in support of a major oilsands project. The scope included the safe handling, indoor storage, and preservation of critical components.

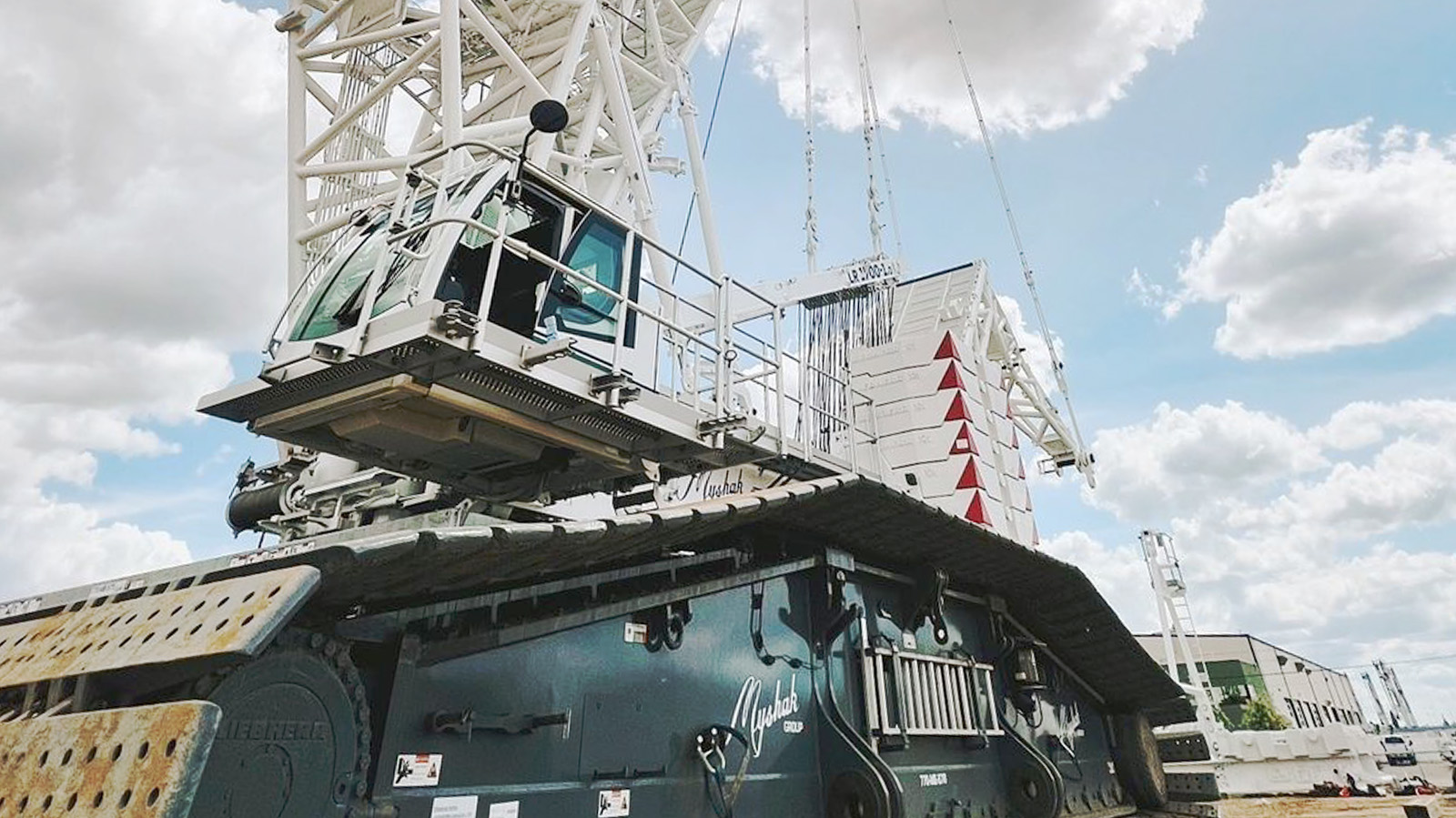

To meet the complex safe handling and storage requirements of the project, the Myshak Warehouse deployed a suite of specialized equipment, including cranes, forklifts, loaders, mod stands, mod beams, and Scheuerle trailers. The use of this equipment was critical during the initial phase and the ongoing storage phase, for safely receiving, transporting, and the placement of components weighing up to 275,000 lbs.

The heaviest units required tandem crane lifts which were executed to safely unload and transfer the components onto Scheuerle trailers. Once secured, the trailers were used to transport and precisely position the heavy loads inside the warehouse facility. This approach ensured both the safe handling and accurate placement while accommodating the limited space and structural load limits within the building.

The central challenge of this project was the handling and indoor placement of the extremely heavy components. While most pieces averaged 35,000lbs, several arrived significantly exceeding that, requiring advanced planning to avoid overloading the facility’s structural capacity. Traditional heavy lift crane methods were not feasible indoors due to height & load limitations. Additionally, each component required preservation in accordance with maintenance specifications to safeguard the condition and functionality ensuring operational readiness. Any error made during storage or preservation could jeopardize these highly critical assets essential to the oilsands facility.

To overcome these challenges, the Myshak Warehouse collaborated closely with internal engineering and concrete specialists to develop a customized material handling strategy. Detailed ground load calculations were conducted to ensure the weight distribution remained within the facility’s safe loading thresholds. Custom built mod stands were fabricated to support and evenly disperse heavy component weights. Mod beams were used to span load points and provide additional stability during placement. Scheuerle trailers were an effective solution for transporting and placement of the heaviest items indoors. These high-capacity, low-profile trailers allowed precise maneuvering within the facility, enabling accurate alignment and placement of components onto the mod stands without overloading any one area of the floor.

Warehousing and preservation personnel established and executed tailored storage solutions for the client. These included regular inspection and routine maintenance cycles to meet the strict preservation standards required for long-term storage. Every asset was maintained to the clients specification, ensuring readiness for future deployment.

Myshak Warehouse continues to carry out the defined scope of this project, with incoming components safely received, stored, and positioned indoors in alignment with storage requirements and all preservation and maintenance criteria. This ongoing work supports a critical oilsands project and reflects Myshak Warehouse’s proven ability to manage heavy and complex loads while integrating project tailored material handling, engineered placement, and long-term preservation into a single seamless and compliant operation.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.