Shell Polaris

Client

Shell Canada

Location

Acheson, Alberta

Industrial / Oil & Gas

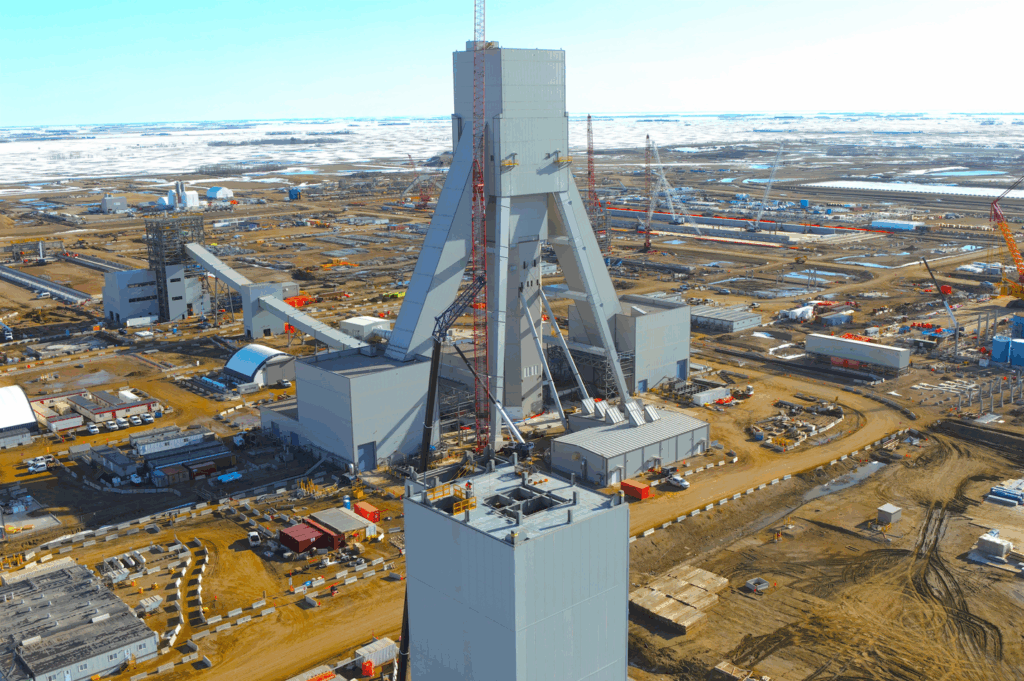

Shell Polaris Project

Business Unit

Warehouse

Project Overview

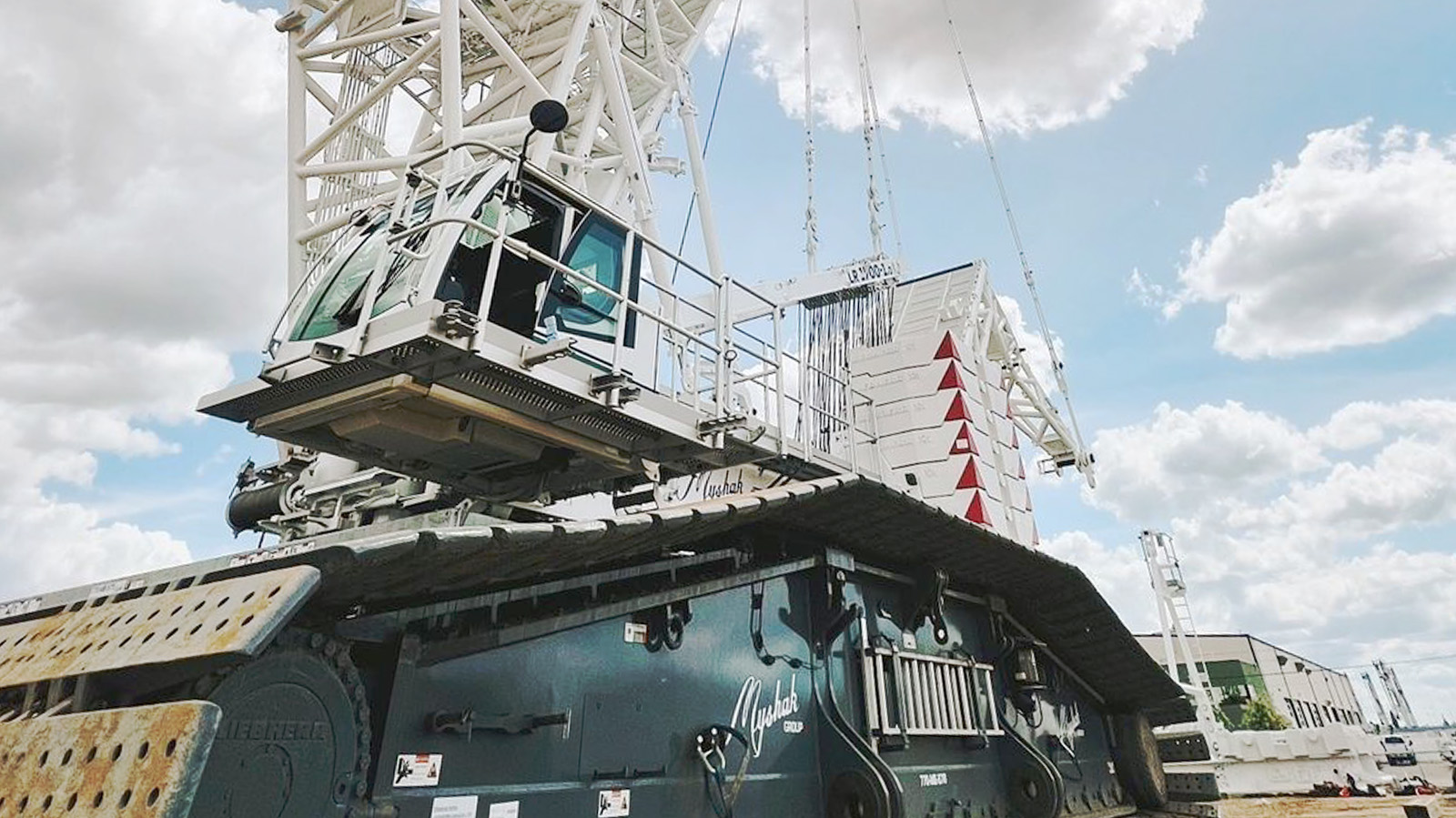

Myshak Warehouse was contracted to provide a comprehensive warehousing solution to support a large-scale industrial materials storage project. The scope of work involved the offloading, receiving, and secure storage of all client supplied materials, including components requiring specialized handling methods. Using cranes, forklifts, and jack and slide systems, the Myshak Warehouse managed the movement and placement of equipment and materials with precision and efficiency. In addition to material handling, the project required ongoing preservation and maintenance services in alignment with both client and OEM specifications.

A total of 67,000 square feet of warehouse space was utilized in order to accommodate all of the assets. This space was organized to support safe traffic flow, maintain material integrity, and allow for preservation activities to be conducted in a controlled environment. Services delivered included the loading and unloading of transport trucks, formal receiving and inspection processes, accurate placement and relocation of materials within the warehouse, and specialized jack and slide operations were used for items that required could not be handled using traditional approaches.

During the execution of the project, certain materials, specifically large building panels, presented a handling challenge due to their structural characteristics. These items required careful weight distribution during unloading and lifting operations to prevent damage and ensure worker safety. The design of the panels meant that conventional rigging techniques were not suitable, as improper sling placement or uneven lift points could lead to material stress or failure. Ensuring the structural integrity of the panels during handling was critical to meeting the project’s quality and safety requirements.

To address the lifting challenge, Myshak Warehouse personnel worked closely with a team of in-house rigging specialists to design and fabricate a custom spreader bar. This tool allowed for even weight distribution and provided designated attachment points for slings, ensuring the panels were lifted in a balanced and secure manner. The spreader bar was engineered specifically for the dimensions and load characteristics of the building panels, allowing for consistent and safe handling throughout the duration of the project. This solution not only protected the integrity of the material but also enhanced the efficiency and safety of loading and unloading operations.

In parallel, preservation and maintenance services were applied across all stored materials in accordance with the client’s and OEM’s technical specifications. Protective measures included rotating shafts, material inspections, and regular upkeep to ensure all equipment remained in a ready state while in storage. These efforts were integrated into the overall warehouse workflow to provide a seamless, end-to-end material management solution.

The project was executed safely, efficiently, and entirely within the defined, agreed upon scope.

Through tailored solutions and precise execution, Myshak Warehouse delivered a full-service warehousing program that met the client’s operational and technical requirements. The combination of experienced personnel, purpose-built equipment, and dedicated preservation services ensured the success of the project from initial receipt through to final storage, reinforcing Myshak Warehouse’s position as a trusted partner for industrial material management.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.