Siemens

Client

Siemens Energy

Location

Acheson, Alberta

Wind

Wind Farm Component Storage

Business Unit

Warehouse

Project Overview

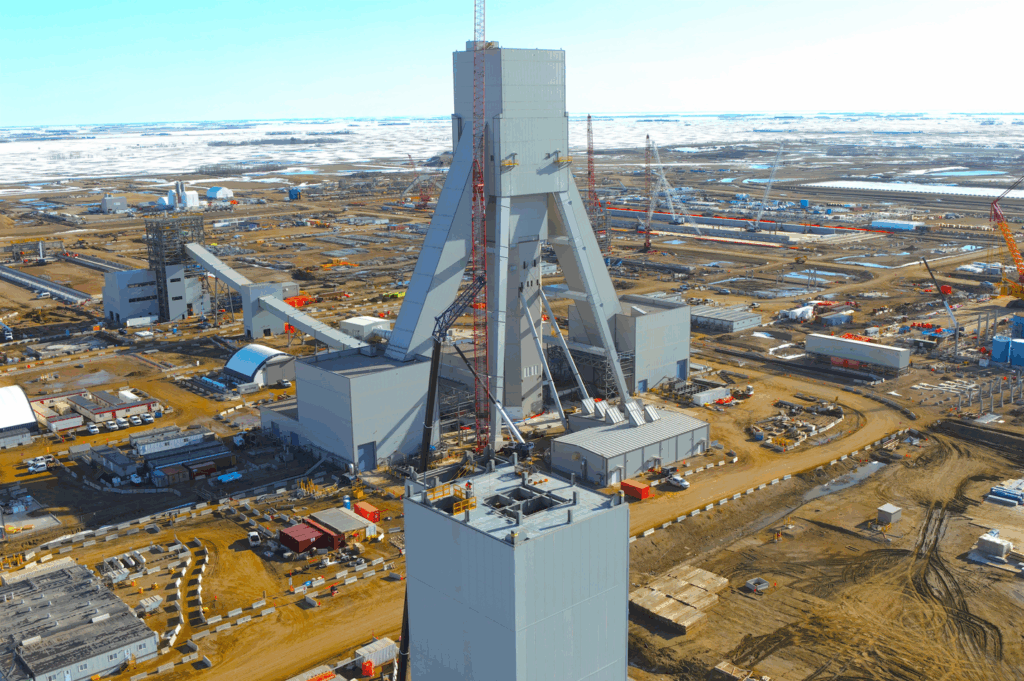

In support of a large-scale windfarm, the Myshak Warehouse was engaged to execute a comprehensive scope of warehousing and logistical support services. The scope of work included offloading and receiving oversized components, jacking and rolling operations, secure indoor heated storage, providing equipment for on-site maintenance crews, and loading materials for outbound transport.

From July 2023 to July 2025, the Myshak Warehouse managed the secure handling and storage of critical windfarm infrastructure. This included main shafts, generators, gearboxes, transformers, coolers, and sea cans containing internal parts. As the project progressed, the scope expanded to include the storage of new, used, and spare parts, as well as surplus materials designated for ongoing maintenance support. All materials were tracked and managed with a focus on traceability, condition preservation, and timely availability for deployment.

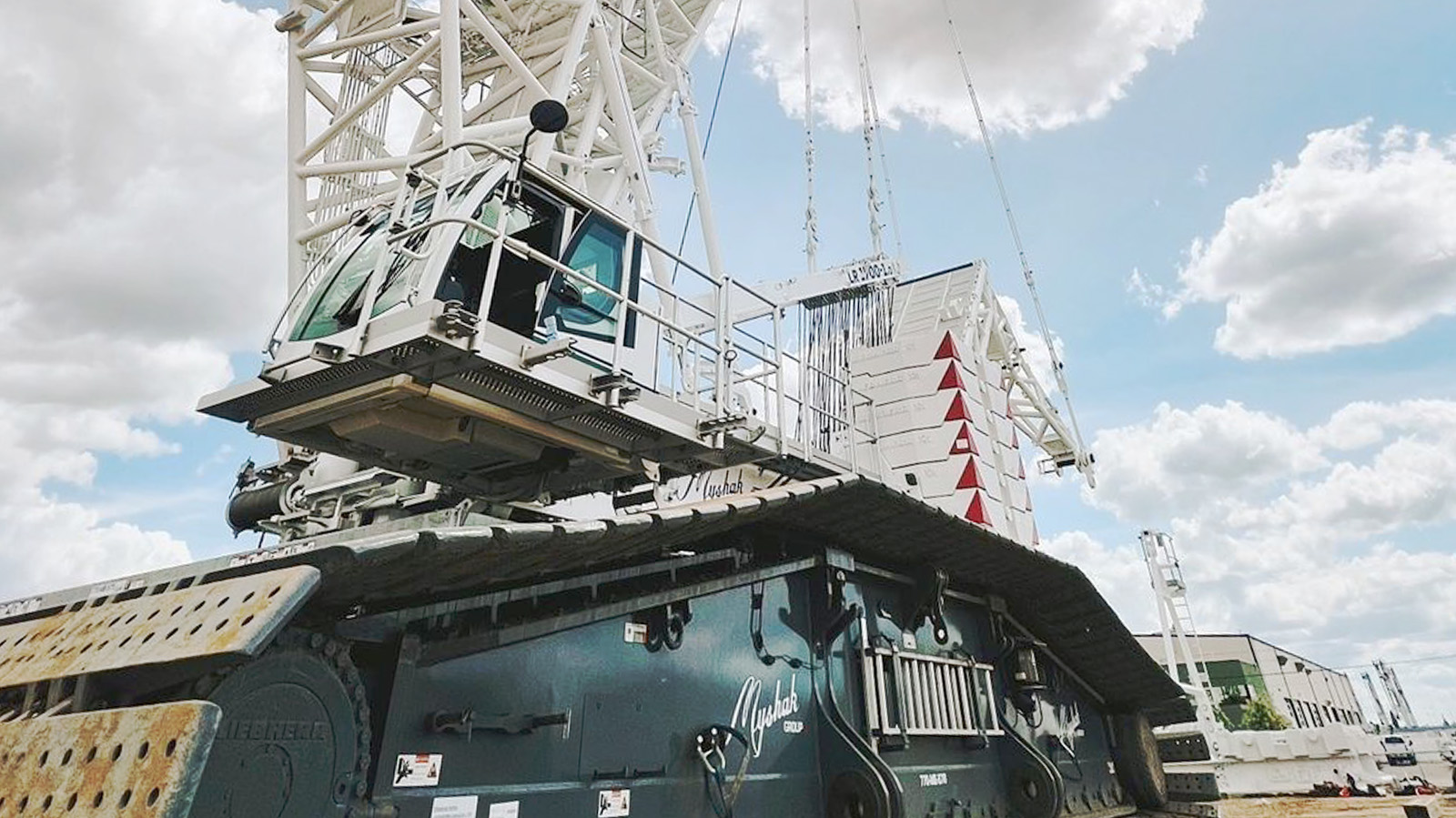

The materials occupied a dedicated 60,000 sq/ft footprint in Myshak’s secure climate-controlled warehouse designed to ensure asset protection and operational efficiency. Equipment storage was strategically organized to support accessibility, preservation, and efficient movement. Specialized equipment was deployed to carry out all handling activities, including a 160-ton Tadano rough terrain crane, forklifts, wheel loaders, and a specialized jack & slide system. Each piece of equipment was selected based on the specific handling and safety requirements of the components involved.

The Warehouse team delivered an integrated warehousing and logistics solution grounded in high safety standards, operational precision, and flexibility. Services included the unloading of incoming transport trucks, thorough material receiving and inspection documentation, and the precise internal movement of components using jack & slide techniques. All stored materials were maintained in a controlled environment to prevent degradation and support long-term asset integrity. Equipment and personnel were made available to support client led preservation and maintenance activities, ensuring minimal disruption and maximum responsiveness. Outbound shipments were coordinated in alignment with project schedules and handled with the same care and control and in compliance with internal handling best practices.

The Myshak Warehouse offered a tailored, scalable solution designed to evolve with the project’s needs. Their approach emphasized collaboration, responsiveness, and adherence to industry best practices. Throughout the duration of the project, all warehousing, handling, and maintenance support services were delivered in line with strict quality and safety standards, ensuring consistent performance and reliability.

The project was successfully completed, with all stored materials and equipment returned to the client in the same or better condition than at the time of receipt. The Warehouse’s consistent and effective execution of their responsibilities showcased a strong ability to maintain high standards in warehousing and logistical support while adapting to evolving project requirements. This outcome underscores Myshak’s commitment to service excellence and further solidifies their reputation as a trusted provider of industrial warehousing and logistical solutions.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.