Simonette

Client

Confidential

Location

Deep Valley, Alberta

Oil & Gas

Simonette River Crossing (Deep Valley HDD Pullback Support)

Business Unit

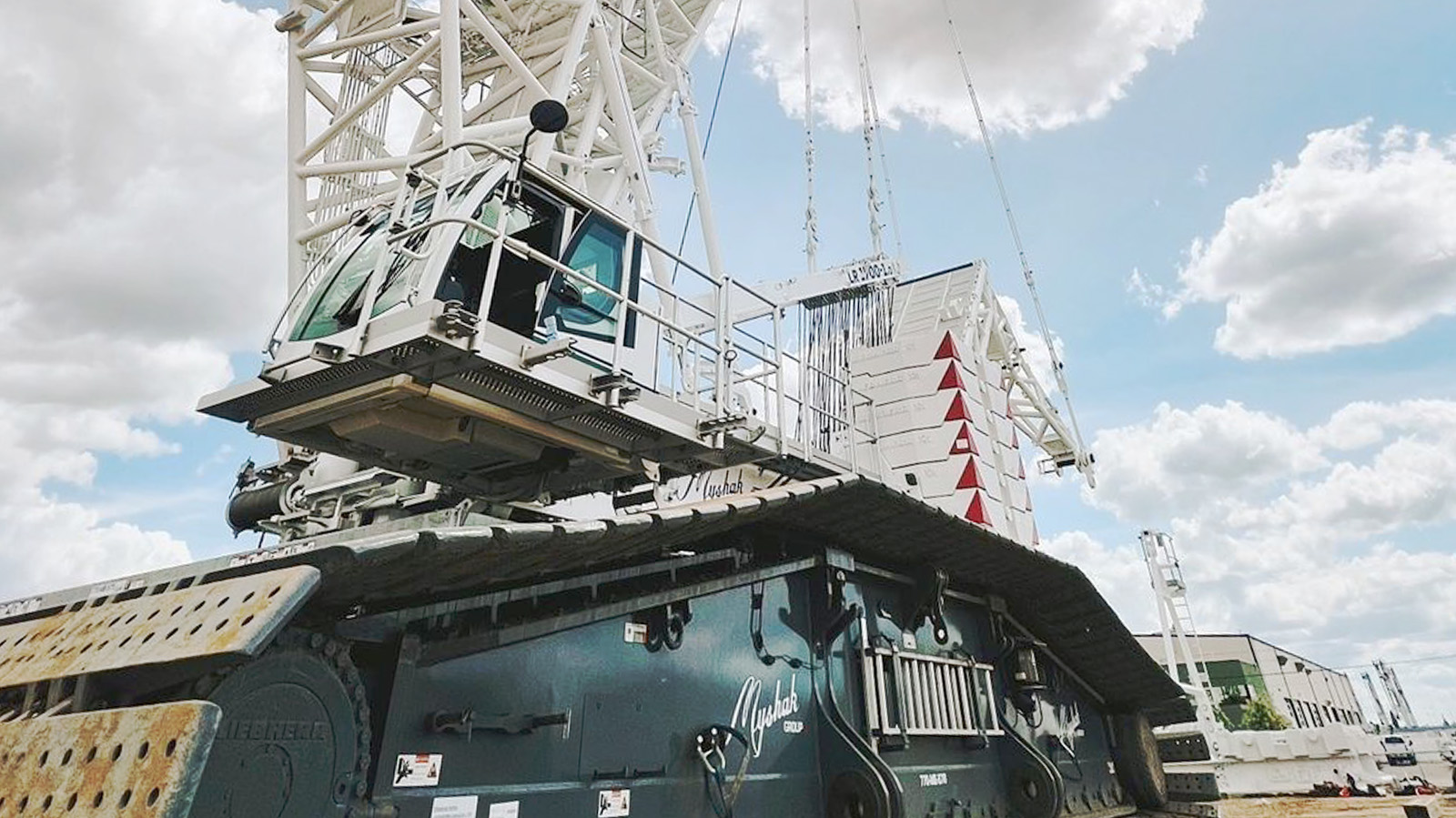

Myshak Crane & Rigging Ltd.

Overview

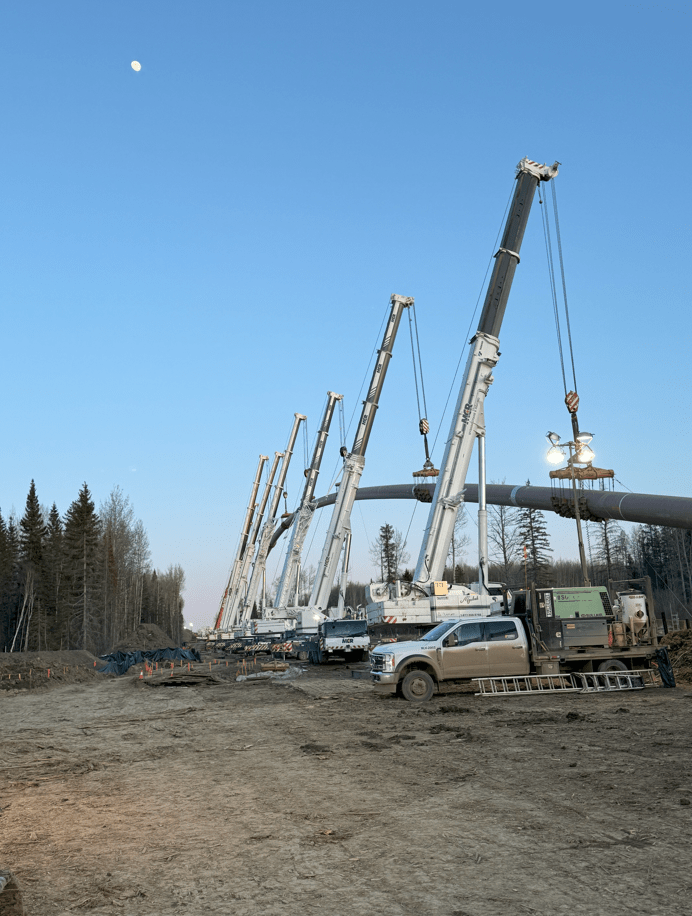

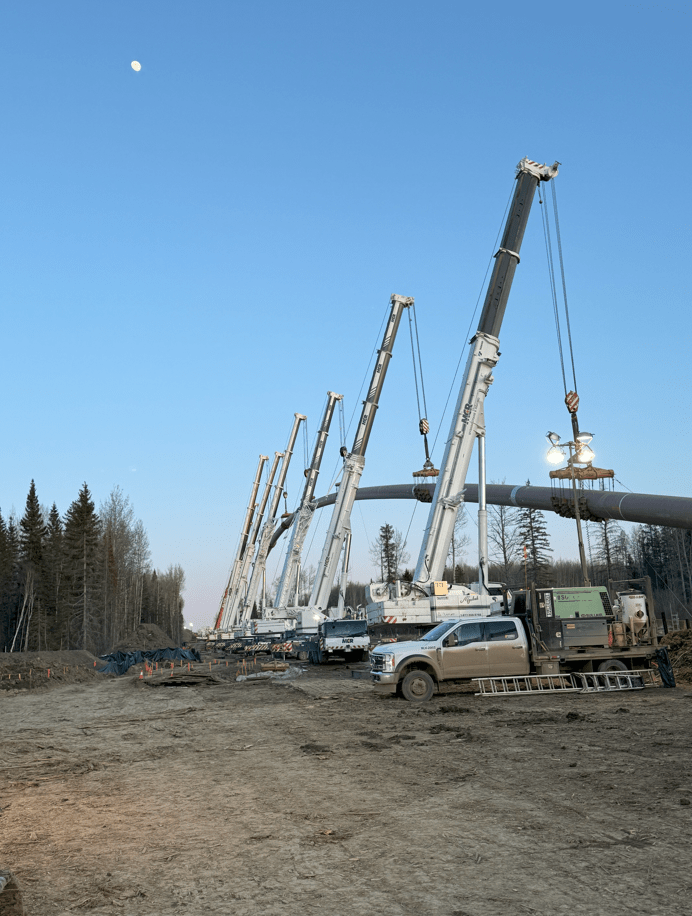

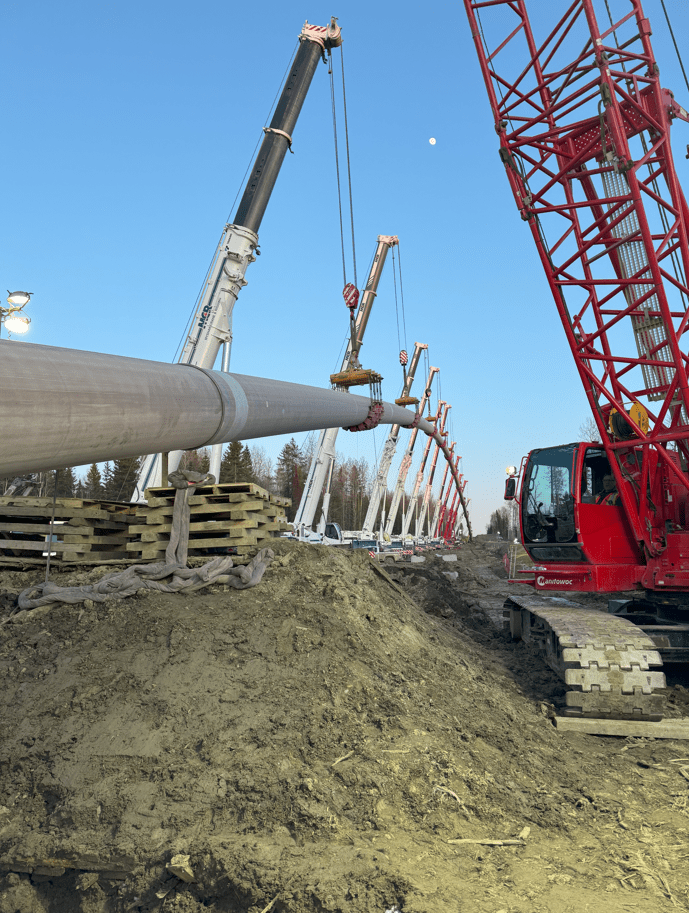

Myshak Crane & Rigging Ltd. (MCR) was contracted to provide full lifting and logistical support for a 1,220 meter HDD pullback at the Simonette River Crossing in Alberta’s Deep Valley. This project required a full mobilization of equipment, personnel, and supervision to the remote site on a highly compressed schedule. MCR was responsible for supplying twelve mobile cranes consisting of five Liebherr LTM1160-5.1 and seven Liebherr LTM1220-5.1 units, to safely hoist and support the pipe during the HDD pullback. MCR coordinated all heavy haul transportation, provided an experienced crew, and delivered onsite technical support and supervision throughout the execution of the operation. The cranes were strategically positioned along the path of the pullback to support and suspend the pipeline at precise intervals, ensuring the pipe remained aligned and elevated throughout the operation. In addition to crane operations, Myshak Crane & Rigging Ltd. (MCR) provided critical input during the engineering and

design phase of the pullback process, working closely with the prime contractor to ensure the feasibility and safety of the lift strategy.

The site location presented multiple challenges. Located approximately 80 kilometers off the main highway, access was limited due to seasonal road bans in effect because of the spring thaw. Road usage was restricted to night travel only, adding another layer of complexity to scheduling and transport coordination. Mobilization was not limited to just the twelve cranes, but also the transportation of sixteen additional loads of counterweights and mats. Time was another significant pressure point. The entire project team had a one week window to complete planning, obtain necessary permitting and road approvals, and mobilize equipment and personnel to site. This included coordinating with multiple stakeholders, such as the client, the road owner, and the pipeline company, all of whom had a role in granting site access.

To address the site’s remote location and limited access schedule, Myshak Crane & Rigging Ltd (MCR) implemented a meticulously coordinated mobilization plan. Detailed scheduling ensured each crane and supporting load departed and arrived on site in sequence, optimizing road usage during the restricted nighttime window. Every truck and crane was required to be outfitted with radio communication equipment, allowing seamless coordination over the controlled access road, ensuring real time updates between all road users and support crews. Close collaboration with the client and all other stakeholders proved to be essential in securing timely access and meeting expectations. MCR’s operations team worked around the clock to orchestrate movement and arrival times, ensuring a predictable mobilization despite the tight timeline and travel limitations.

MCR successfully mobilized all equipment and personnel, completed the HDD pullback operation, and fully demobilized from the site within the allotted week, despite the remote location, access restrictions, and limited planning time. Myshak Crane & Rigging Ltd.’s proactive planning, experienced team, and collaborative approach were instrumental in delivering the project safely and efficiently. MCR’s ability to perform under pressure and deliver comprehensive lifting support in a remote environment reaffirmed

their reputation for safe, dependable, and agile project execution.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.