Big Horn Mine

Client

Confidential

Location

Hinton, Alberta

Mining

Big Horn Mine Project

Business Unit

Energy Crane, Myshak Sales & Rentals Ltd., Myshak Transportation Group

Overview

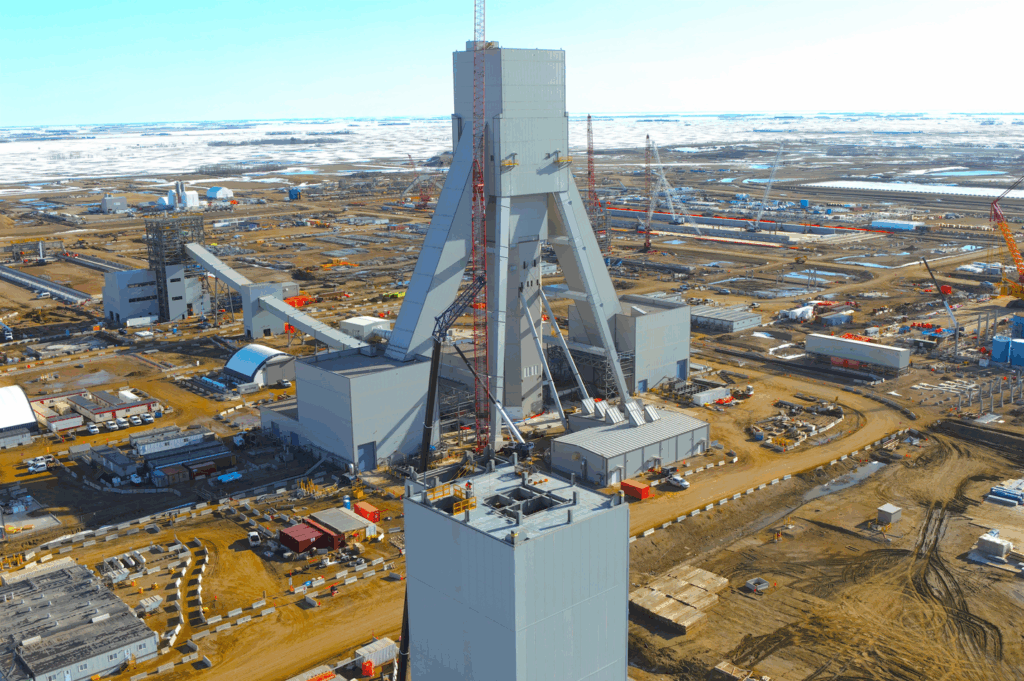

The Big Horn Mine (Vista Coal Mine), located approximately 10 kilometers east of Hinton, Alberta, is a large open pit coal operation situated along the eastern slopes of the Rocky Mountains. Energy Crane was engaged to provide crane services for equipment assembly, structural steel erection, and the installation of nearly 15 kilometers of conveyor systems. The project’s remote mountain location and the complexity of the required lifts called for a highly mobile and responsive crane solution capable of withstanding rugged conditions.

To meet the demands of the site, Energy Crane deployed a fleet of rough terrain cranes specifically selected for their mobility, maneuverability, and ability to operate in challenging environments. These cranes supported a high volume of tandem lifts, necessitated by the size and configuration of structural components. Advanced rigging systems and custom lift planning tools were utilized to support these operations, ensuring precision and safety. Energy Crane’s depth of experience in executing tandem lifts proved essential to maintaining progress across a constantly shifting worksite.

Reaching the site involved traversing a 9-kilometer unpaved road with a substantial incline. Once on location, crews encountered unstable ground conditions that affected nearly every lift location. Each lift required detailed execution plans and customized rigging adapted to the variable terrain. Given the weight and scale of the conveyor and equipment components, tandem lifts became standard practice. Meanwhile, severe mountain weather characterized by fluctuating temperatures, snow, and high winds further impacted scheduling and crane performance. Due to these constraints, crawler cranes were not a viable option, reinforcing the need for a mobile fleet and agile operational planning.

Energy Crane managed the full scope of mobilization, lift planning, in field rigging design, and tandem lift execution. Cranes were repositioned regularly to support ongoing construction activities across the site’s expansive footprint. Each lift was engineered with consideration for equipment capability, environmental conditions, and ground stability. Rigging configurations were designed on site to accommodate the unique requirements of each lift, ensuring safe and efficient execution without costly delays.

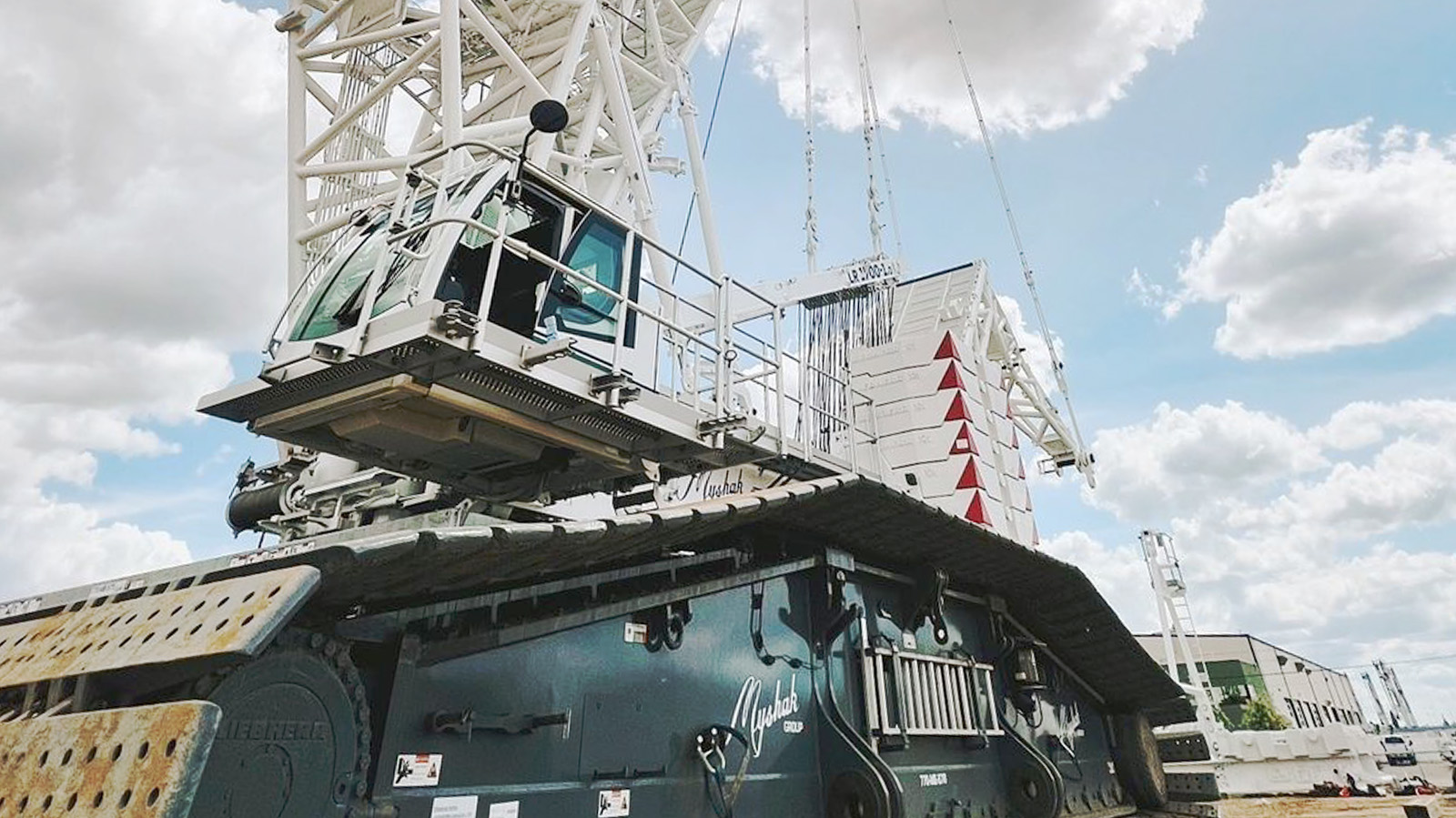

Operational success was bolstered by coordinated support from other companies within the Myshak organization. Myshak Sales & Rentals (MSR) supplied dedicated fuel and lubrication trucks to sustain crane operations throughout the remote, demanding site conditions. Myshak Transportation Group (MTG) managed the transport of cranes and support equipment to and from the mountain site, facilitating timely mobilization and demobilization without interrupting the project schedule.

Energy Crane successfully delivered the project on time and in full alignment with client specifications. The combination of strategic lift planning, adaptive rigging solutions, and integrated logistical support enabled the team to overcome the environmental and operational challenges presented by the site. This project reflects Energy Crane’s capability to execute complex, large scale lifting operations in some of the most remote and technically demanding industrial environments in Western Canada.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.