Great Plains

Client

Confidential

Location

Moose Jaw, Saskatchewan

Industrial/Power Generation

Great Plains Power Station

Business Unit

Energy Crane

Overview

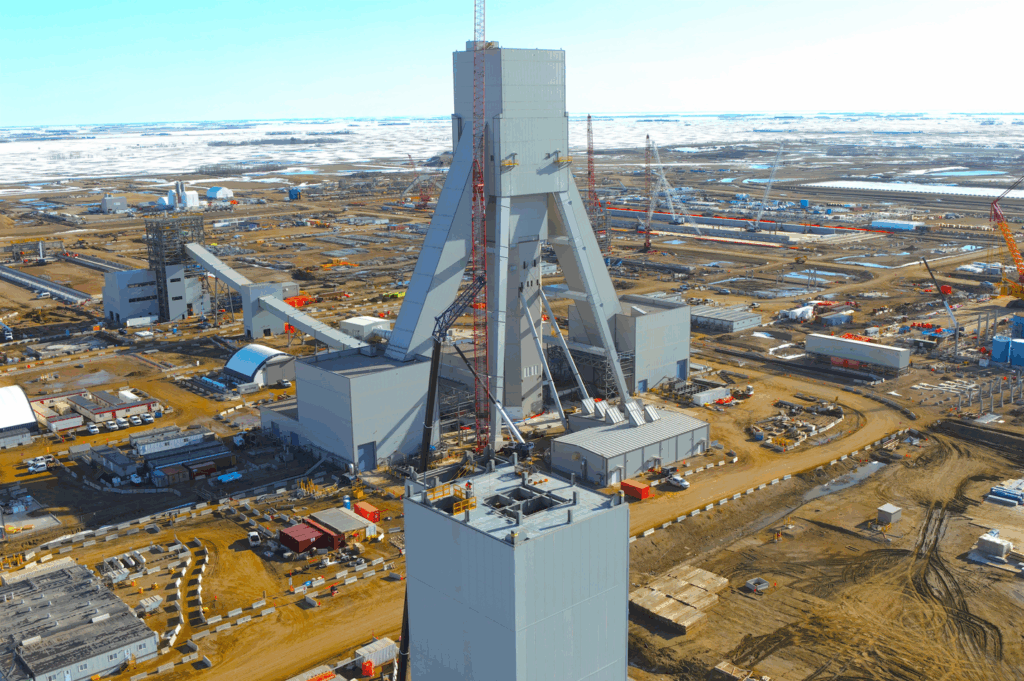

The Great Plains Power Station project in Moose Jaw, Saskatchewan, tasked Energy Crane with executing complex crane operations under demanding site and environmental conditions. Working simultaneously for two separate contractors, one responsible for mechanical installations and the other for air cooling unit placement, the project required a high level of precision, coordination, and adaptability throughout its duration.

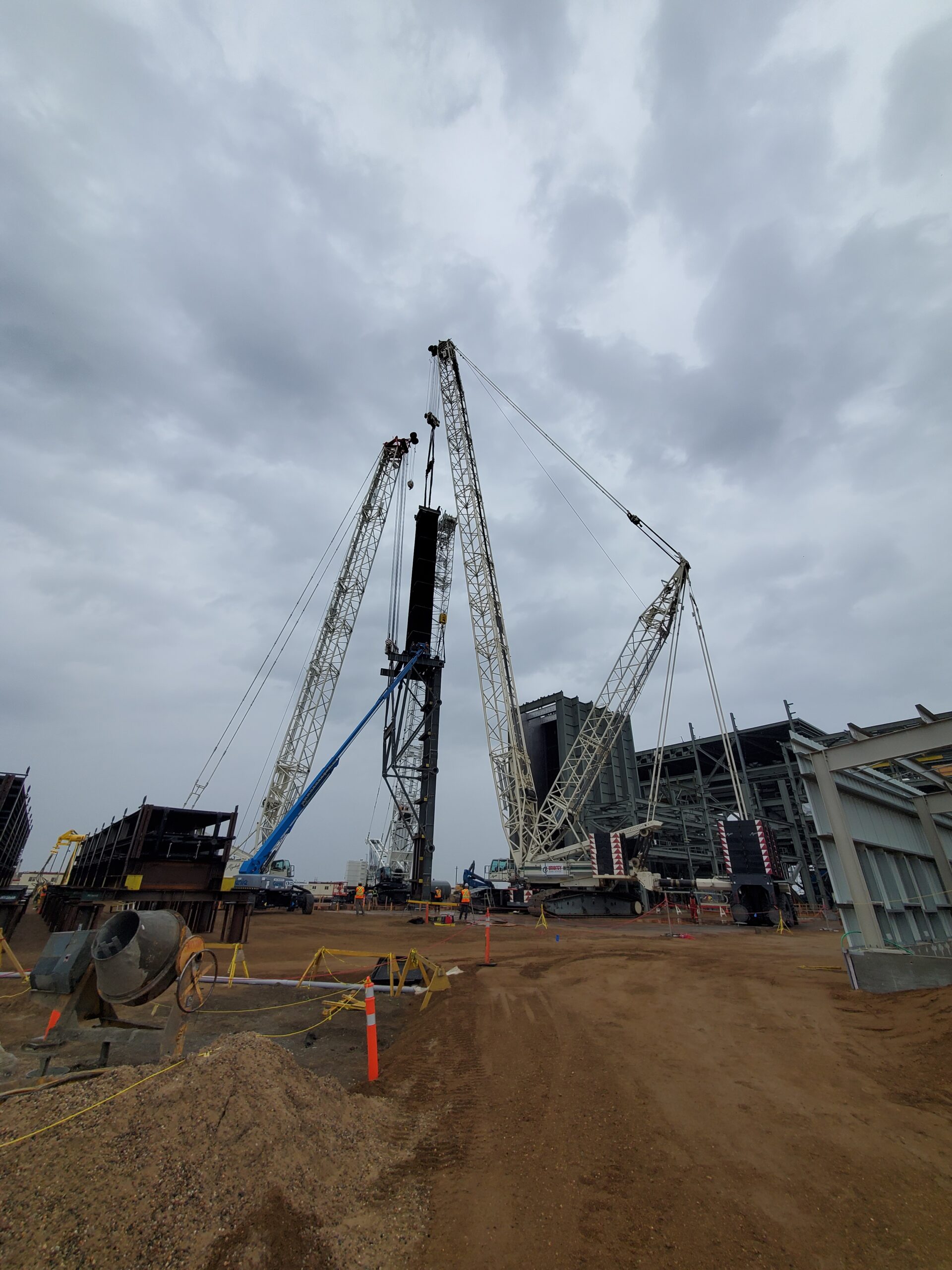

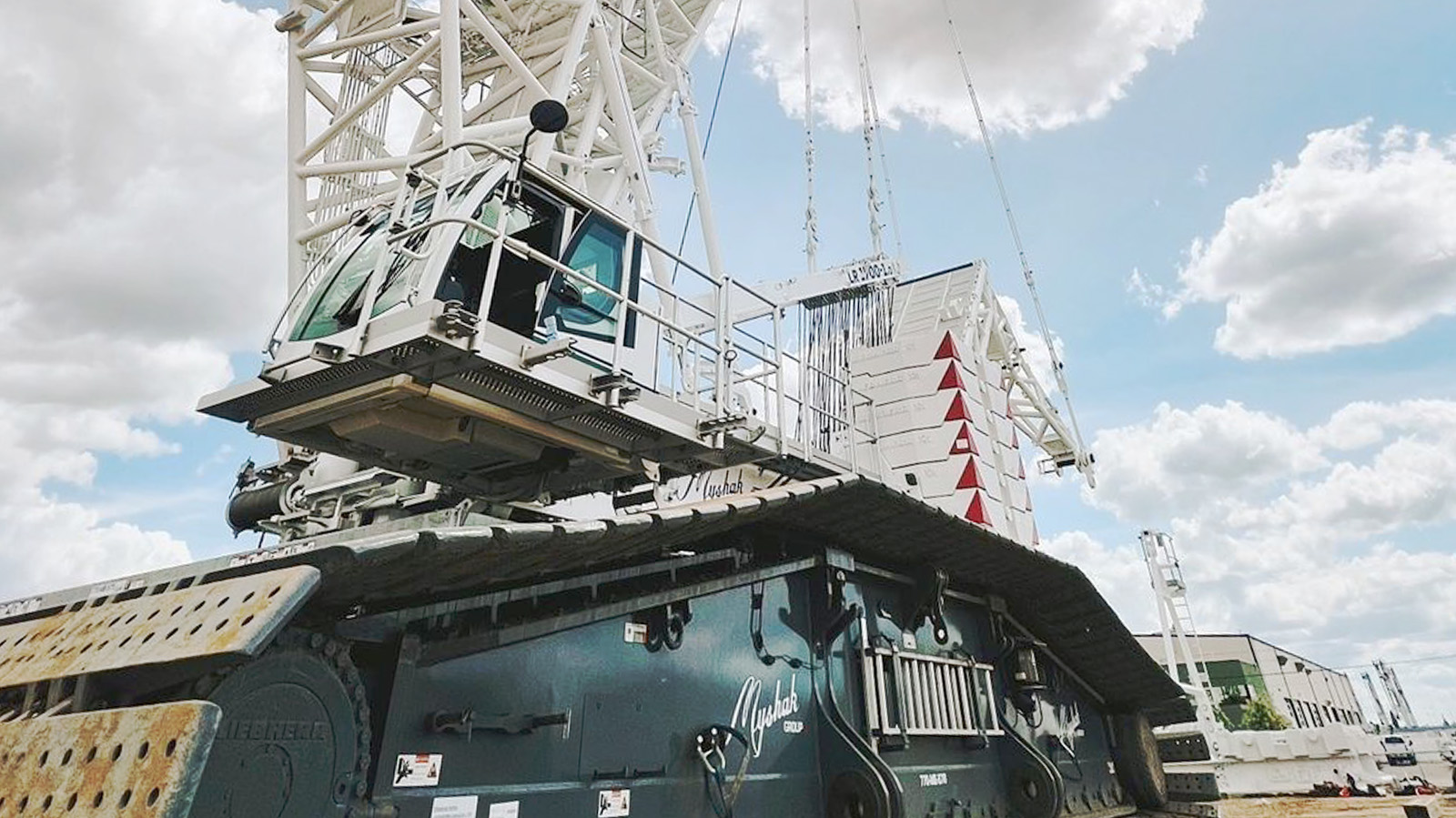

Energy Crane supplied, mobilized, assembled, and operated all heavy lift equipment on site. The fleet included two 660-ton Demag CC2800-2 Crawler Cranes, a 330-ton Kobelco CK3300G Crawler Crane equipped with a luffing jib, and several smaller rough terrain cranes. These machines supported a variety of critical activities, including module and bundle setting, mechanical installations, laydown operations, and the placement of air cooling units.

Mobilizing this equipment presented a significant logistical challenge. The crawler cranes and their support components had to be delivered and assembled within a confined work area with limited laydown space. This required meticulous coordination of transport trucks and multiple cranes arriving in rapid succession. Despite the spatial constraints, the assembly and deployment of equipment was carried out safely and without any operational disruptions.

Several key challenges tested the team’s capabilities. Energy Crane had to simultaneously support two contractors operating on different timelines and scopes. The project also involved complex three crane lifts of heavy, awkwardly shaped loads that required exact synchronization and seamless communication between operators. Additionally, the harsh Saskatchewan weather, characterized by high winds, sub- zero temperatures, and snow posed a constant threat to both crew safety and operational windows.

These challenges were met with a strategic and proactive approach. Every major lift was preceded by detailed planning, especially those involving multiple cranes. Scheduling was continuously adjusted in real time to take advantage of favorable weather conditions, including conducting overnight lifts to avoid daytime wind gusts. Regular on site coordination meetings were held with both contractors to align schedules, lift windows, and equipment requirements. Equipment was kept in peak condition through rigorous maintenance protocols and winterization measures to ensure reliable performance in cold weather.

Experienced operators, supported by a dedicated Crane and Rigging Supervisor, managed each critical lift with precision. The complex three crane operations were executed with millimeter level accuracy, all completed safely and on schedule without any incidents or delays.

At the end of the project, Energy Crane successfully delivered both scopes of work to the complete satisfaction of the clients. Despite a demanding logistical timeline, limited space, and challenging weather conditions, the project was completed with exceptional efficiency and safety. The Great Plains Power Station project underscores Energy Crane’s capability to manage heavy lifting operations in demanding environments, demonstrating a strong ability to support multiple contractors and deliver consistent results across overlapping scopes.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.