Aspen Project

Client

SaskPower

Location

Lanigan, Saskatchewan

Power Generation

Heavy Transport & Gantry Offload – Aspen Project

Business Unit

NexGen Transportation

Overview

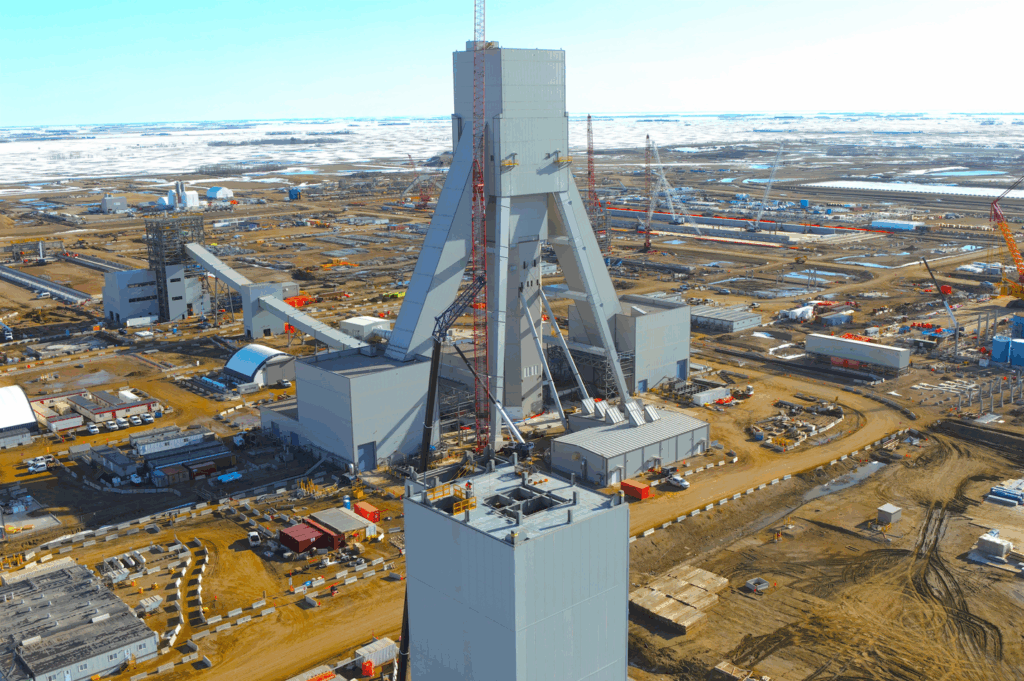

The Aspen Power Station Project, located west of Lanigan, Saskatchewan, is a major infrastructure project led by SaskPower. This project for NexGen involved the delivery and installation of critical industrial components for the construction of a 370-megawatt natural gas facility, set to come online in 2027. The initial portion of NexGen’s scope of work now successfully completed focused on the offloading, transfer, and transportation of oversized, high-value cargo from rail to the project site. The next stage of the project took place on site and focused on the precise positioning and installation of these components.

Among the most technically demanding pieces that needed to be relocated was a gas turbine generator (GTG), which, once loaded weighed over 859,649lbs in its transport configuration. Transporting this and other large components safely and efficiently required a strategic approach, cutting edge equipment, and precise coordination across multiple teams and jurisdictions.

One of the most significant challenges encountered during the over the road stage was identifying a suitable rail siding capable of supporting the size, weight, and movement of both the cargo and the specialized transport equipment. Due to limited rail infrastructure in the area, the search for a viable siding involved months of strategic planning and multiple days of on site assessment and verification. Every effort was made to find the most efficient, least disruptive option, ensuring local traffic, infrastructure, and residents of surrounding communities were respected throughout the process. After a thorough evaluation process, a siding was selected based on its technical feasibility and its potential to avoid unnecessary disruptions.

Once the siding was confirmed, considerable work was required to upgrade the existing access road. Corners were regraded, surfaces were improved, and a staggering amount of access mats were installed to establish a solid, level area from the access road entrance to the siding for the gantry setup. This stable base was essential for both the offloading and transport operations, allowing heavy equipment to move safely on and off site without incident.

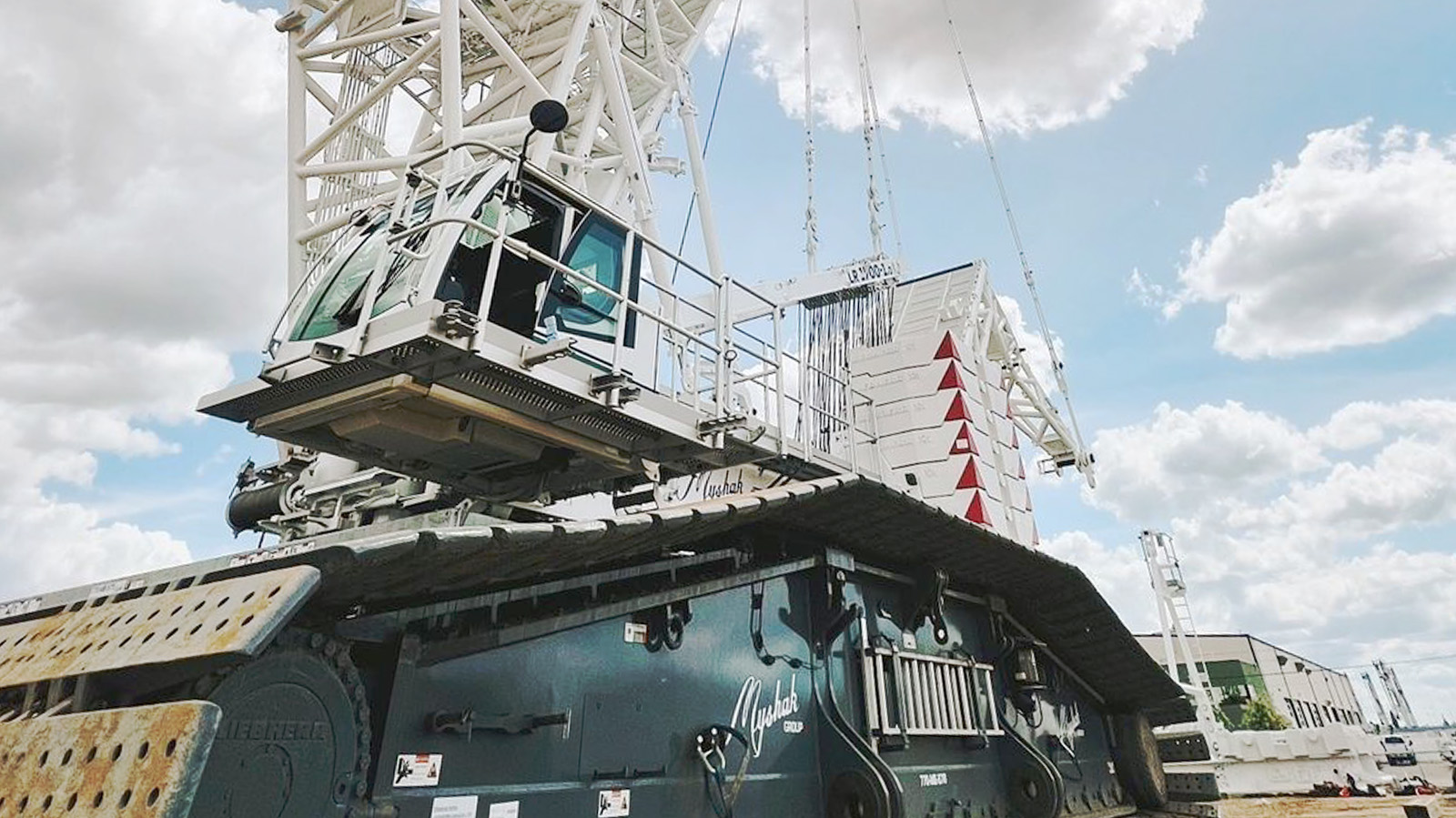

To execute the rail offload, NexGen deployed its new 700-ton electric gantry system, the first of its kind operating in Canada. This project marked the inaugural use of the gantry, introducing a new standard of capability and flexibility for heavy lift operations in the country. The gantry system was engineered for versatility, featuring multiple header sizes (8m, 10m, and 12m) up to 360 feet of track able to accommodate a broad range of applications and project requirements. NexGen’s in house design and fabrication team engineered and produced new track sections and lift links tailored specifically to this project’s unique requirements, ensuring a precise and reliable fit.

The gantry itself is equipped with a range of advanced features, including drive motors on each tower to allow for synchronized travel, lift, and side shift. A built-in anemometer monitors wind conditions in real time, ensuring operational safety throughout the lift. The system is controlled by a wireless remote, which provides the operator with live, loaded, and per tower weight readouts, ensuring full visibility and control during all phases of the lift. All crew members operating the gantry have been factory trained by Enerpac and their partners at Engineered Rigging, further reinforcing NexGen’s commitment to safety, precision, and performance.

Each component was safely offloaded from its railcar and transferred onto hydraulic platform trailers for transport to the Aspen Power Station site. A total of 18 individual loads were moved using two prime movers, a skilled trailer operator, and a dedicated support team consisting of a supervisor, project manager, pilot vehicles, picker truck, and additional support trailers. Load scheduling was closely coordinated with CN Rail and flagging crews to ensure safe timing between train traffic and offloading operations. Despite the project’s complexity and tight timelines, all cargo was successfully offloaded and delivered to site without delay.

The project then transitioned to the installation stage, where the delivered components were assembled and installed on site. This stage involved repositioning the equipment using both the gantry and jack and slide systems. Due to the site layout and varying surface conditions, there were specific areas where the gantry could not be used. In these sections, the jack and slide system bridged the gap, allowing for seamless movement of components until the gantry could resume operations. The same equipment and skilled crews involved during transport were redeployed for installation, including both prime movers, a smaller site trailer, trailer operators, supervisors, the gantry crew, and jack and slide specialists.

This project represents not only a significant milestone for SaskPower but also a major advancement in Canadian heavy lift capabilities. The introduction of NexGen’s 700-ton electric gantry system not only set a new benchmark for Canadian lifting operations, it also brought new versatility and precision to the industry, with the potential to transform how oversized equipment is handled in future projects across the country. Through innovation, strategic planning, detailed engineering, and close coordination, the Aspen Power Station project continues to move forward on time and on track to deliver reliable power to Saskatchewan by 2027.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.