Vancouver Project

Client

Confidential

Location

Vancouver, British Columbia

Industrial

Rail Car Dumper Replacement

Business Unit

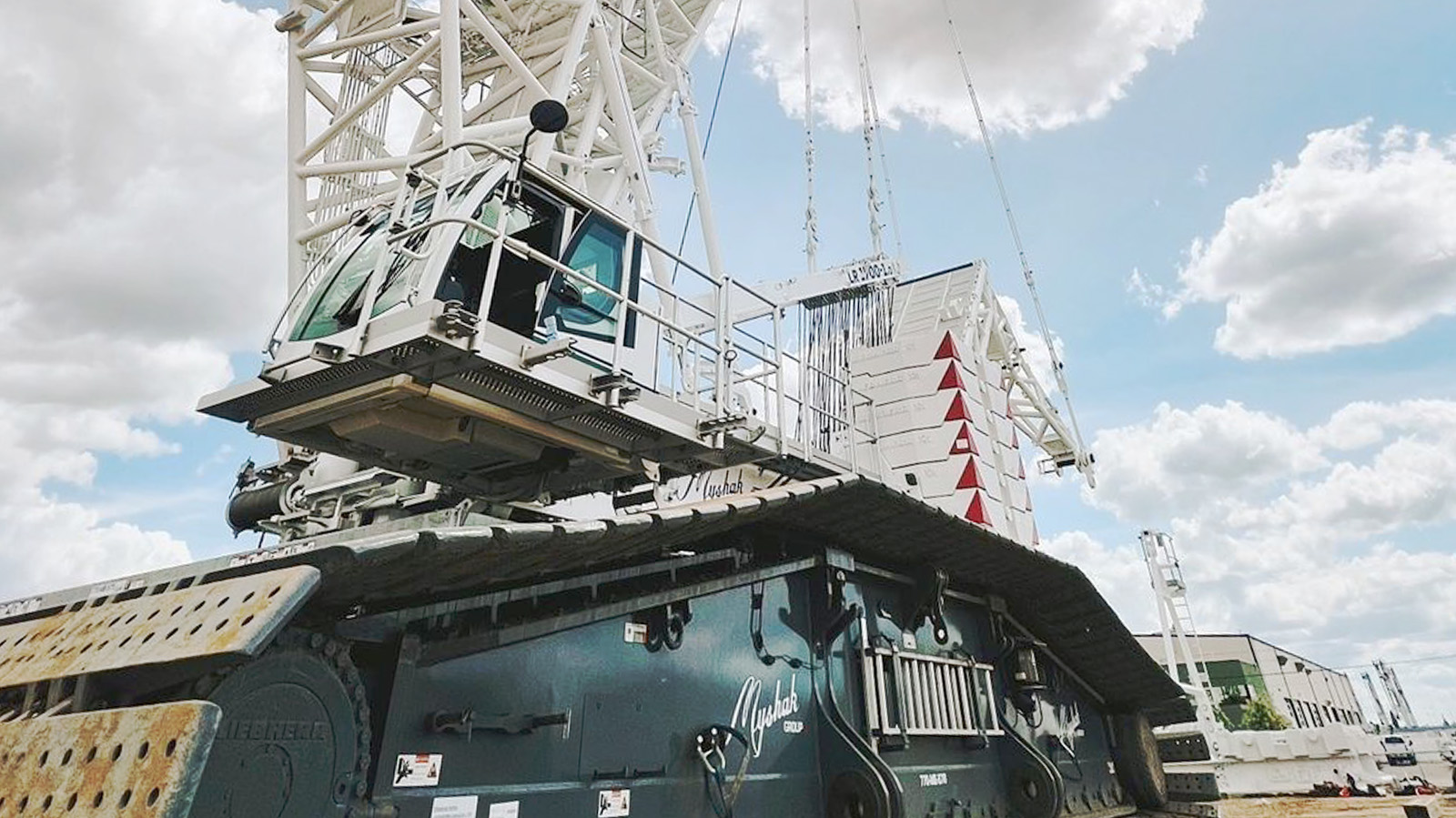

Myshak Crane & Rigging Ltd., NextGen Transportation

Overview

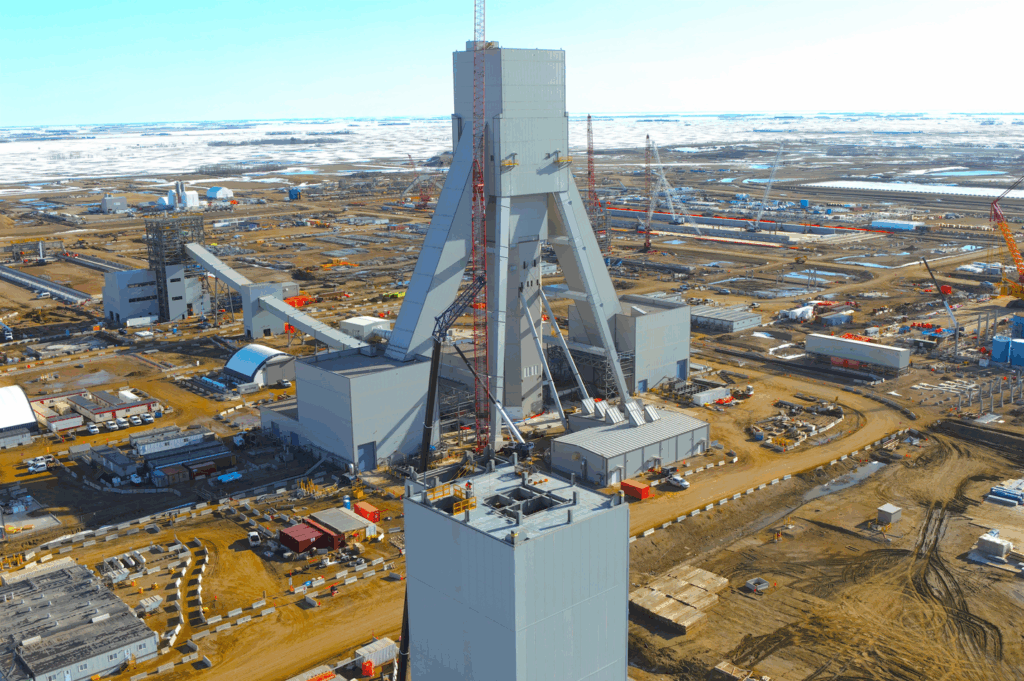

Myshak Crane & Rigging Ltd. (MCR), in partnership with NexGen, was contracted to support the replacement of a critical rail car dumper used for unloading sulfur at a major industrial facility in Vancouver, British Columbia. The project involved a full equipment upgrade, requiring the removal and installation of both the dumper and its surrounding housing structure. This complex operation was executed within a strict 30 day scheduled outage, with no margin for delay.

Given the high-risk nature and significant operational impact of the project, more than a year of meticulous planning and coordination was required to ensure successful execution. Numerous site visits and collaborative planning sessions were conducted with the client, engineering consultants, and operational teams to address every aspect of execution, safety, and schedule alignment. Among the primary planning priorities was coordinating the facility outage to minimize disruption to adjacent operations, while also addressing the risks posed by active live rail traffic. The project required the development of comprehensive lift plans, careful sequencing of logistics, and navigating the transportation of crane components through mountainous terrain during unpredictable winter conditions.

To complete the scope of work, MCR mobilized 38 loads of equipment from Acheson, Alberta to Vancouver, carefully managing route logistics through the challenging Coquihalla Highway in March where snowfall and highway closures are frequent. Strategic planning was essential to ensure deliveries arrived in sequence for crane assembly, avoiding on site congestion due to limited staging space. All components were shipped and received in numerical order to streamline the build of the LR1700.

Once on site, the team assembled the LIEBHERR LR1700 crawler crane within the confined work zone. The main crane, configured with an HSL3DBV boom, featured a 276-foot boom length and a 140-foot lift radius, providing the capacity to efficiently lift the 385,000lbs dumper. It was supported by 418,900lbs of crane counterweight, 110,200lbs on the carbody, and an additional 826,700lbs on the super lift. The LIEBHERR LTM1220 was used as an assist crane, outfitted in a T-configuration with 75,000lbs of counterweight.

To manage the transport and precise positioning of critical components, NexGen provided a comprehensive suite of heavy haul and jacking equipment, including two prime movers, four file 8-line Scheuerle trailers, a Hydra-Slide rail system, and 100-ton locking collar jacks. This equipment was instrumental in facilitating the safe relocation of the existing building structure and dumper, as well as ensuring the precise installation of the replacement units.

The execution phase began with MCR lifting the existing 60’ x 60’ x 45’, 120,000lbs building structure off its foundation in a single piece and setting it onto NexGen’s 4 file 8-line trailer. The building was then relocated to a designated laydown area and self-offloaded onto blocking. Following that, the existing rail car dumper, measuring 35 feet in diameter, 50 feet in length, and weighing 385,000lbs was lifted from its foundation and placed onto the same trailer for transport to the laydown area, where it was disassembled.

While the site team worked to rebuild and prepare the foundation, the jacking crew slid the newly assembled dumper, approximately 375,000lbs, off its temporary foundation and onto the 4 file 8-line. At the same time, the new building was jacked to a height of 48 inches, allowing it to be self-loaded for transport when needed. Once the foundation work was complete, the new dumper was moved into position at the crane, where MCR executed a precision lift, setting the dumper onto its foundation within millimeters of its final operating location.

NexGen then returned to the laydown area, self loaded the new 120,000lbs building, and moved it to the crane. MCR lifted the new structure off the trailer and installed it over the dumper, securing it onto its foundation to complete the installation.

Once all of the lifts were completed, the LR1700 was disassembled and demobilized back to Acheson. Throughout the operation, MCR maintained a full-time on-site team that included a Crane & Rigging Supervisor, two LR1700 operators, one rigger, and one assist crane operator.

The project was delivered safely on time, and within the client’s 30-day scheduled outage. Despite adverse weather and numerous logistical complexities, the operation was completed without incident or injury. The crew worked through challenging conditions and adapted daily to changing site demands. This successful execution highlights the strength of the partnership between MCR and NexGen and demonstrates their combined ability to manage technically demanding industrial lift and relocation projects with precision, safety, and professionalism.

Similar Projects

Elevate Your Next project.

We’re always here to help, so connect with our team today.