Store

Staging, Storage and Maintenance

Our Core Storage Services

Storage

Indoor Storage Capabilities

- Over 200,000 square feet of available indoor storage space

- Capacity to accommodate loads up to 300,000 pounds

- Oversized overhead doors for large equipment access

- Equipped with 14 high capacity loading docks for efficient handling

Outdoor Storage Capabilities

- More than 20 acres of secure outdoor storage area

- 24,000 square feet of covered outdoor storage space for weather sensitive materials

Preservation

Our team is committed to operational excellence, helping clients reduce downtime, protect valuable equipment and maintain project efficiency. This commitment is reflected in our comprehensive preservation program, which encompasses a range of proven methods designed to safeguard equipment integrity from the time of receipt through to final delivery. Preservation practices include regular cleaning to remove dirt, dust, and debris, as well as the application of corrosion inhibitors and lubricants to minimize wear and friction. Equipment is sealed to prevent moisture and contaminants from compromising functionality, and are stored in controlled environments that regulate temperature, humidity, and ventilation to mitigate environmental risks. We ensure all materials are placed in appropriate storage locations and positioned correctly using dunnage, blocking, or pallets to prevent distortion or degradation. Security measures are implemented to deter damage or theft, while preventive maintenance schedules and routine inspection protocols help ensure long-term reliability and performance. All activities are carefully documented, with accurate record keeping maintained from initial intake through the duration of the storage term. Our team consists of properly trained and competent Millwrights who uphold high standards in every aspect of preservation, including emergency preparedness measures such as spill containment and fire protection planning. This disciplined approach ensures our clients’ assets are protected and project timelines are maintained without compromise.

Handling

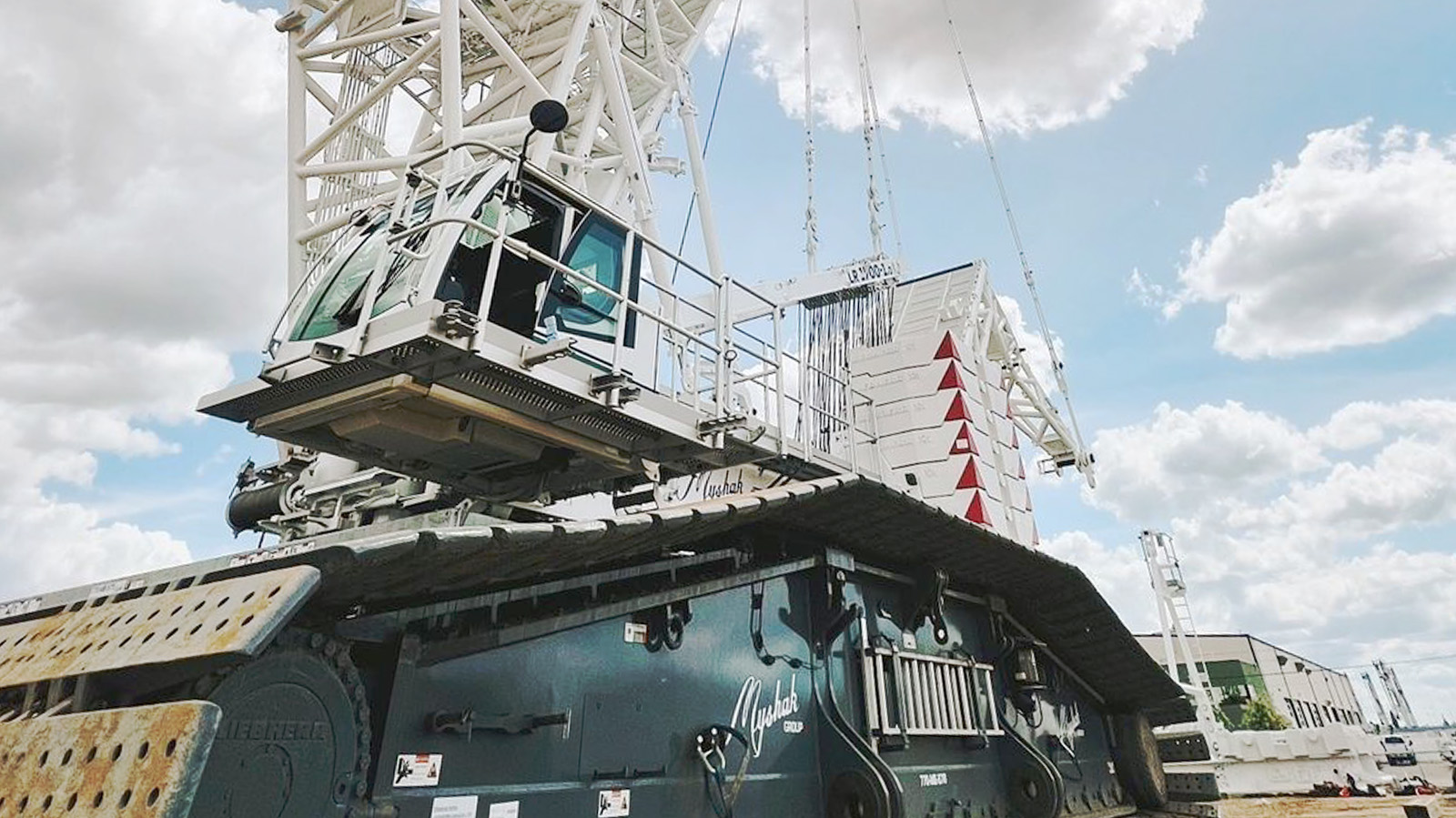

Myshak provides a robust fleet of material handling equipment to support project needs. Our forklift inventory includes units with lifting capacities ranging from 5,000 to 35,000 pounds. Wheel loaders are available in sizes ranging from 15,000 to 30,000 pounds, offering the versatility required for heavy material movement. For precision heavy load positioning, we offer a 160 ton Tri-Glide dolly system, enabling safe and efficient movement of oversized equipment. In addition, we provide crane support services with lifting capacities from 10 to 160 tons. For projects requiring larger capacities, we have seamless access to heavy lift solutions through other specialized divisions within the Myshak organization, ensuring we can meet the demands of even the most complex lifting requirements.

Jack & Slide

Jack and Slide systems provide a precise and controlled method for relocating heavy loads within our warehouse, particularly where crane access is impractical or vertical clearance is limited. To further enhance our capabilities in moving oversized components in confined spaces, Myshak has integrated a 160 ton Tri-Glide dolly system. This addition enables the safe and efficient maneuvering of large components into confined areas without disrupting surrounding operations.

Store Case Studies

Contact

Toll Free

1-877-960-9790

Phone

780-960-9790

Fax

780-960-9791

28380 Acheson Road,

Acheson, AB, T7X 6A8

Elevate Your Next project.

We’re always here to help, so connect with our team today.